Zucker- und Stärkeindustrie

Herold Wendelkolben®-Pumpen

Gerade in der Zucker- und Stärkeindustrie ist die Wahl der richtigen Pumpe entscheidend. Herold gewährleistet mit seinen Verdrängerpumpen seit über 20 Jahren den reibungslosen Betrieb.

Stillstand kostet Geld. Gerade bei normalen Pumpen versagen bestimmte Bauteile zum falschen Zeitpunkt. Unsere Pumpe bietet die in der Zuckerindustrie benötigte Prozess-Sicherheit durch ein durchdachtes und robustes Design. Und neben der weltweit niedrigsten Pulsationsrate hat die Herold Wendelkolben®-Pumpe zahlreiche weitere Vorteile:

- Volumenkonstanter, kontinuierlicher Förderstrom

- Betriebssichere Gleitringdichtung (Eigenentwicklung)

- Nur eine Pumpe – sowohl für niedrig-, als auch für hochviskose Medien

- Großes Förderspektrum

- Energiesparendes Förderprinzip

Typical Product Applications

- Dicksaft

- Kristallfuß-Magma

- Weißzucker-Magma

- Rohzucker-Magma

- Nachprodukt-Magma

- Weißzucker-Ablauf

- Rohzucker-Ablauf

- Affinations-Magma

- Melasse

Beliebte Modelle

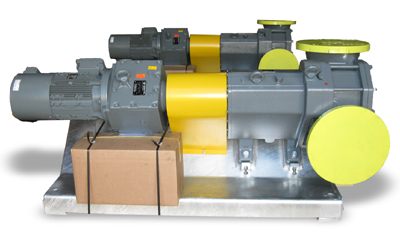

02.350

Unsere Drehkolbenpumpe 02.350 wurde speziell für extrem große Fördermengen entwickelt. Die Viskosität spielt dabei keine Rolle. Die Pumpe kann sowohl zur Melasseverladung (z.B. mit 500 m³/h) als auch für hochviskose Medien eingesetzt werden.

- Produkt: Massecuite A

- Viskosität: 180.000 mPa·s

- Fördermenge: 125 m³/h

- Druck: 4,5 bar

- Drehzahl Pumpe: 64 min⁻¹

- Antrieb: 55 kW

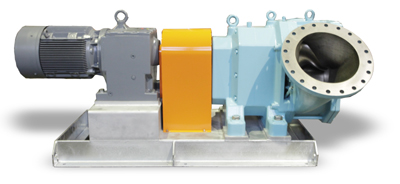

02.100

Unsere Pumpe ist auch für extrem hohe Viskositäten ausgelegt. Durch einen vergrößerten Einlass kann das Medium einfacher in die Pumpe fließen.

- Produkt: Kühlmaische-NP-Magma

- Viskosität: 2.000.000 mPa·s

- Fördermenge: 25 m³/h

- Druck: 7 bar

- Drehzahl Pumpe: 43 min⁻¹

- Antrieb: 22 kW