Sugar and starch industry

Herold Wendelkolben®-Pumps

Choosing the right pump is crucial, especially in the sugar and starch industry. Herold has been ensuring smooth operation with its positive displacement pumps for over 20 years.

Downtime costs money. Particularly with normal pumps, certain components fail at the wrong time. Our pump offers the process reliability required in the sugar industry thanks to its sophisticated and robust design. And in addition to the world’s lowest pulsation rate, the Herold Wendelkolben®-Pump has numerous other advantages:

- Constant volume, continuous flow rate

- Reliable mechanical seal (in-house development)

- Only one pump – for both low-viscosity and high-viscosity media

- Wide range of funding

- Energy-saving conveying principle

Typical Product Applications

- Thick juice

- Crystal foot magma

- White sugar magma

- Raw sugar magma

- By-product magma

- White sugar drain

- Raw sugar process

- Affination magma

- Molasses

Popular models

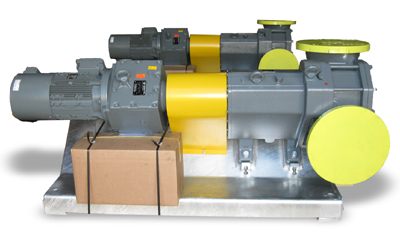

02.350

Our 02.350 rotary lobe pump was specially developed for extremely high delivery rates. The viscosity is irrelevant. The pump can be used for molasses loading (e.g. with 500 m³/h) as well as for highly viscous media.

- Product: Massecuite A

- Viscosity: 180,000 mPa-s

- Delivery rate: 125 m³/h

- Pressure: 4.5 bar

- Pump speed: 64 min-¹

- Drive: 55 kW

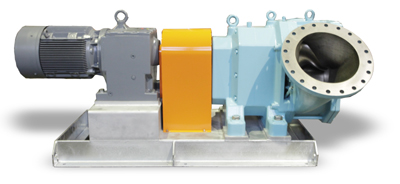

02.100

Our pump is also designed for extremely high viscosities. An enlarged inlet makes it easier for the medium to flow into the pump.

- Product: Cooling mash-NP-Magma

- Viskosität: 2.000.000 mPa·s

- Delivery rate: 25 m³/h

- Pressure: 7 bar

- Pump speed: 43 min-¹

- Drive: 22 kW